For over a hundred years, the Jeantet Group has weathered storms and celebrated triumphs. Through decades of challenges and victories, we’ve stayed true to the legacy of those who came before us.What follows highlights our journey, paying tribute to the men and women who’ve fueled this adventure with their grit and ingenuity.

Every month on LinkedIn, we roll out a fresh chapter of our company’s saga. Dive into 120 years of stories, woven together through a tapestry of themes that showcase our evolution. For rubber buyers and automotive manufacturers, this isn’t just a history lesson—it’s proof that your search for the ultimate provider of rubber and elastomer moulded parts ends here. The next step? Reach out to us.

Picture this: the late 19th century, and Saint-Claude proudly wears the crown as the pipe-making capital of France. The Jeantet family is already a big player, running Jeantet-David, a pipe-making outfit founded in 1816.

By the early 20th century, though, there’s a catch—every single pipe stem comes from Germany. That’s a problem when demand is booming.

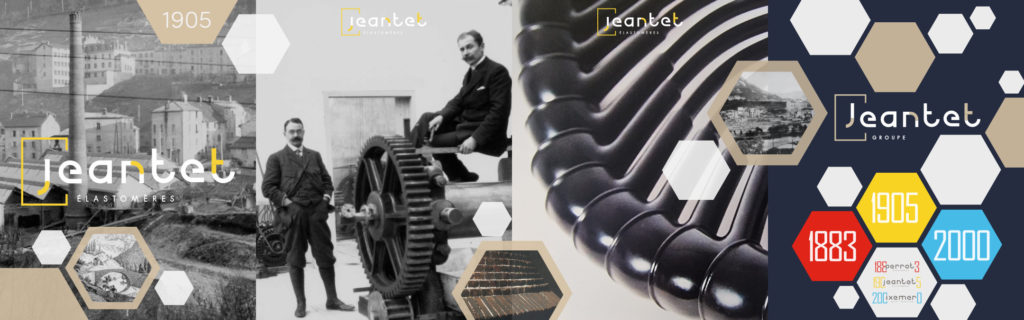

Enter Paul and Maurice Jeantet. In 1905, they spearhead the creation of “L’Ébonite,” a bold move to break free from German imports and master the tricky art of transforming this thermosetting, moldable material.

It’s not smooth sailing at first—ebonite’s a tough nut to crack. But Paul teams up with chemist Georges Morard, and together they crack the code. There’s even a vintage photo of the duo posing with a mixing cylinder: Paul standing tall beside it, Georges perched atop it like he’s conquered the beast.

Soon, production kicks into high gear. Over 100,000 pipe stems roll out daily, supplying Saint-Claude’s pipe makers with top-notch quality. The Jeantet name starts to mean something: innovation, independence, and excellence.

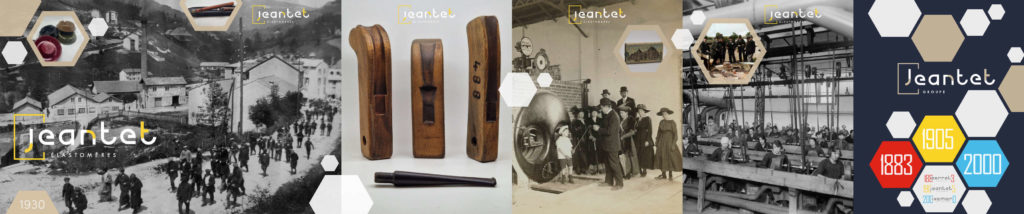

By 1930, renamed Paul Jeantet et Cie, the company realizes it can’t just rest on its pipe-stem laurels. Diversification is the name of the game. Ebonite proves versatile, and soon they’re churning out combs, clarinet mouthpieces, and even medical supplies.

This expansion gets a major boost in 1917 with a second factory in Gennevilliers (just outside Paris). It’s a big deal—complete with a ceremonial laying of the first stone and the firing up of the boilers. Paul Jeantet’s eldest son gets the honor of striking the first match, a symbolic spark for what’s to come. The Gennevilliers plant starts to produce ebonite goods and dives into PVC production too.

Fast forward to 1965, and François Jeantet makes a strategic call: shut down Gennevilliers and refocus everything in Saint-Claude. The goal? Become the specialist in soft rubber.

At its peak, the combined Saint-Claude and Gennevilliers sites employed nearly 1,000 people. By the end of France’s post-war boom, the workforce is around 150 in Saint-Claude—a leaner, meaner operation ready for the modern era.

Through it all, the Jeantet Group has stayed obsessed with mastering rubber-related crafts: mixing, molding, finishing,pouring their hearts into in-house training and career growth, ensuring their expertise stays sharp and relevant. Over the years, they’ ve employed everyone from carpenters and sculptors to mechanics, pipe benders, and polishers—proof of versatility and attention to detail.

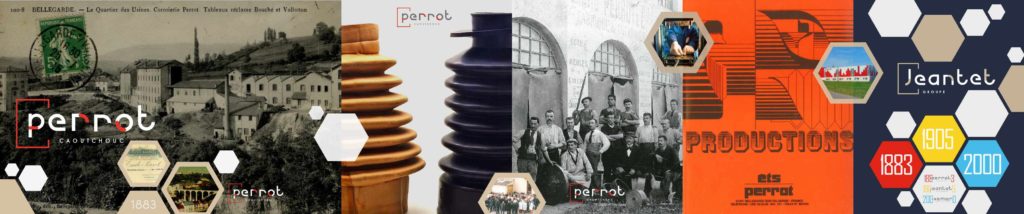

It all began in 1883, when Émile Perrot, a Swiss entrepreneur, founded a tannery-roasting plant in Bellegarde-sur-Valserine, in the Ain. On his death, his sons Henri and Georges took over the reins of the company, which became Perrot Frères. For almost 80 years, the company specialized in leathers, but the evolution of demand led to the abandonment of the tannery sector in the early 1960s.

Faced with industrial transformations, Perrot Frères is moving towards a new field: sealing rubbers, becoming a key player in Europe. This ability to innovate marks a strategic turning point for society.

It specializes in the manufacture and processing of natural and synthetic elastomer products, used to manufacture machined joints, bellows, and all types of technical rubber parts.

In 2007, Perrot was acquired by the Jeantet group, which refocused the site’s activities on the manufacture of custom-made precision parts. The Bellegarde-sur-Valserine site provides the group with a complementary product range in existing markets. Jeantet Elastomères brings its expertise in the formulation of rubbers and Perrot its expertise in machined joints. In 2020, the Perrot brand is integrated into the Jeantet company and its values are perpetuated every day by all teams.

The Jeantet Group has consistently prioritized innovation to deliver cutting-edge products to its clients. In 1905, ebonite represented a pioneering material. During the post-war economic boom of the Trente Glorieuses, rubber enabled the mass production of products that enhanced living standards and met evolving consumer demands. By the late 20th century, new plastic materials emerged, challenging rubber’s dominance. Thermoplastic elastomers (TPEs) combined flexibility with ease of processing, marking a significant advancement.

Leveraging its expertise in vulcanizable elastomers, the Jeantet Group initiated a strategic diversification project in 2000, spearheaded by Frédérique Jeantet. This led to the establishment of Ixemer, a subsidiary dedicated to thermoplastic elastomers, based in Saint-Claude in partnership with Jean-Pierre Grosfilley. Ixemer introduced an innovative technology: multi-material thermoplastic injection molding. This process enables the simultaneous molding of multiple materials using a single machine, eliminating the need for assembly or secondary processing. Concurrently, Ixemer launched a new range of an historic Jeantet product – boat trailer wheels wheels, originally manufactured in rubber since the 1950s.

In 2003, Ixemer introduced an innovative range of soft-touch, dual-material pens, driving significant growth and necessitating the construction of a new facility. The company gained recognition for its teams’ expertise in developing high-precision technical products. Equipped with seven rotary-base machines and Billion presses manufactured in Oyonnax, Ixemer strenghtened its operational capabilities. The synergy between Jeantet and Ixemer expanded the Group’s product offerings, providing clients with a complementary range of solutions.

In 2024, Ixemer relocated its manufacturing site to Martignat in the Ain department to support its ambitious growth objectives. In 2025, Ixemer celebrates its 25th anniversary.

Why This Matters to You

If you’re in the rubber or automotive game, you’ve just stumbled across a company with over a century of know-how, a knack for innovation, and a relentless drive to deliver quality. From pipe stems to precision elastomer parts,Jeantet has honed its craft through every twist and turn of history.

Your search for the best rubber and elastomer molded parts provider is over ! Now it’s time to get in touch. Let’s talk about how Jeantet can drive your next project with the expertise only 120 years of experience can bring.