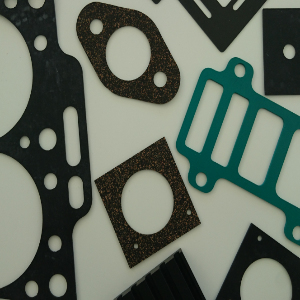

At JEANTET Elastomers, we produce and mould a wide range of materials for rubber plates, including: NBR, EPDM, NR, FKM Viton®, FVMQ Fluorosilicone, Silicone, HNBR Therban®, ACM Vamac®, PU, BR, CR Neoprene®, CSM Hypalon®, IIR butyl, ECO Epichlorohydrin, SBR, NBR-Cork, HNBR-Cork. See also our rubber formulation page.

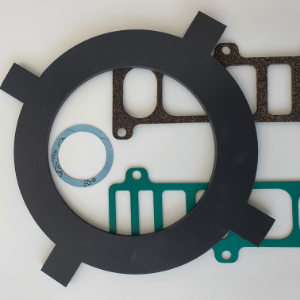

Our cutting workshop and design office produces all manner of gaskets, plates, rubber seals on high-precision digital tables.

We offer small and large runs with no size limitations and short lead times, for a variety of rubber and elastomer uses :

We offer a selection of materials that meets the needs of our clients and satisfies today’s standards by compliying with our extensive tests, such as :

Our seals are made from plates moulded in-house, and they benefit ISO 9001 technical and quality control. This means they benefit from an excellent level of traceability, unlike products cut from standard plates.

JEANTET Elastomers also offers additional services tailored to our clients’ assembly requirements, such as various sizes and shapes of seal pouches, special packaging and marking. You can read more about our expertise on our history page